About us

WHO WE ARE

Founded in 1998, MSN Mason, a subsidiary of Baxter, focuses on the brand of nursing appliances and is committed to creating a distinctive and exquisite charm for men all over the world.

Adhering to the brand concept of “appearance and strength, creating a pleasant experience for customers”, MSN Mason joined the project incubation and acceleration camp of the Barn College in 2017.

Focusing on the proposed product design, together with the design teams of Huawei Honor, Barn, Auger, and Red,

Combining the black technology research and development strength of the Baxter brand factory, we will strive to create an independent brand that adheres to originality and innovation.

From product touch, extreme shape, to exquisite and simple visual experience, MSN Mason’s brand attitude of “enjoying life and enjoying life” has been poured into it.

Since 1998, we have been a leader in providing high quality electronics at exceptionally low prices

Global market share in 2023

eCommerce

Global Personal Care Industry Leader

Relying on rich 49+ international brand OEM experience, the layout of the entire industrial chain of 5 categories of personal care provides an inevitable space for selection of products for traditional, live broadcast, and social e-commerce.

Zhejiang personal care and beauty instrument production base

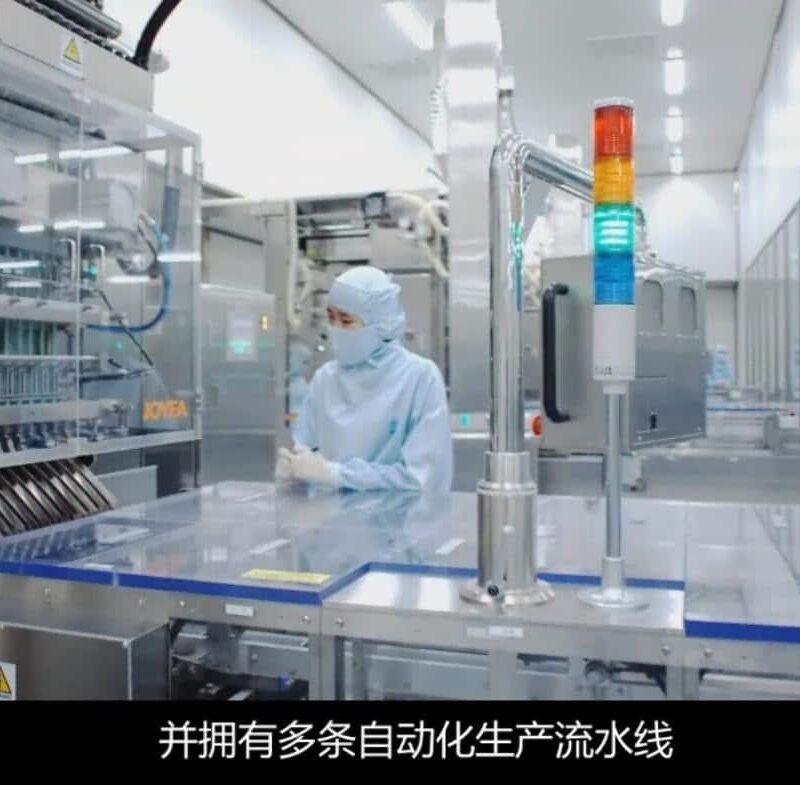

Covering an area of 40,000 square meters, 23 assembly lines, in line with internationalization The personal care and beauty instrument production factory provides high-end beauty instrument products.

Jiangsu personal care shaving production base

Covering an area of 85,000 square meters, it focuses on high-end R&D and production of shaving, grooming, nose hair trimming, etc., and builds a global advanced level of automated production lines.

Production base of all categories in Vietnam

Invest huge sums of money in overseas factories in Vietnam, and deploy on five continents around the world 180+ countries and regions continue to develop overseas markets.

The three major factories have a daily output of 80,000 units/piece/part

Possess international and domestic advanced production equipment, implement intelligent production in many fields, meet GMP standard production environment, senior professional production team, more than 50 automated production lines in 100,000-level medical device-level dust-free purification workshops own motors There are more than ten fully automatic assembly lines in the factory, which can adjust the motor according to the product specification and solve the production capacity efficiently

SGS/BV/ITS/TUV authorized RoHs tester/transmission simulation tester/UV tester, constant temperature and humidity tester/power tester/coil and rotation tester/blade hardness and sharpness tester/material tester/battery and unit life experiment cabin/noise experiment cabin, etc.